Abstract:Pipe fittings are essential for effective pipe and...

Pipe fittings are essential for effective pipe and heating systems in many homes and businesses. They make the process of moving liquid or gasses through pipes much easier by creating the right diameter, length, angle, and other factors necessary for the pipe to serve effectively. There are a wide variety of different types of pipe fittings available for use in different applications.

One of the most common types of pipe fittings is the hexagonal cap. This is commonly referred to as a "cap," because it looks like a cap. A hexagonal cap has threads that line up in a series instead of cutting into the pipe. The threads will spin when the cap is turned, which helps to keep the threads lined up so they don't break. This type of cap has smaller diameter threads than other types, so they are not as useful in smaller diameter pipes.

Another popular type of pipe fittings is the external threaded valve, which can be used to regulate internal pressure in piping. These types of valve bodies have internal threads that are externally visible. They can be used to help maintain proper flow rates, because they are designed to counter varying pressures. Some external threaded valve bodies even feature slotted seats inside of them, so they can be seated into a specially designed slot at the far end of an opening pipe. Seat seating helps keep the seat from getting bumped, causing unwelcome leaks.

Other commonly used pipe fittings include reducers and bushings. Reducers work by increasing the inside diameter of a pipe, which allows more room for air to flow through it. Bushings, on the other hand, prevent the inside of a pipe from expanding, so water that is put through it doesn't leak out. They are sometimes used to help with reducing friction in a pipe, which can improve efficiency. When it comes to reducing friction, though, bushings and reducers are much less effective than what people usually think of when they talk about pipe fittings.

When talking about pipe fittings, there are two different types of couplings to talk about: metallic and plastic. A metallic coupling is one that consists of a threaded portion and a metal portion. The metallic couplings usually come in various sizes, depending on the pipe that they are needed for, so it's important to get the right size to start with. Plastic couplings, meanwhile, are made from a material called PVC, or polyvinyl chloride, which has some nice advantages over metal. Plastic is completely safe for use in any pipe, so there's no worry about getting the joint overheated or becoming brittle under the heat of use.

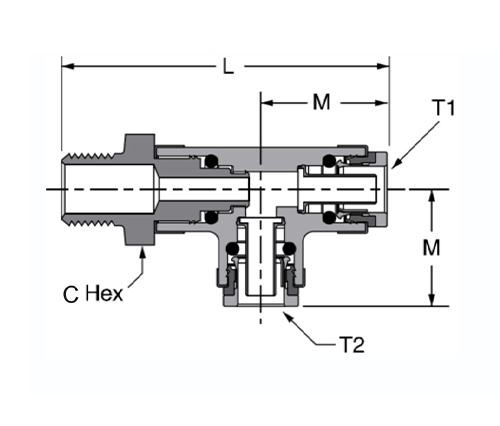

The most common type of pipe fittings are those that involve joints - either loose or tight. For example, there are tee and nut sets that connect two different pieces of piping. Tee drums usually have a hexagonal arrangement of six to eight tee nuts, while nut clusters usually consist of sixteen to twenty-four. Couples are often secured by a washer, which can be either a lock washer or a pop-head screw, depending on the style of coupling in question.

There are also various types of plug valve systems that use air pressure to keep the fluid inside the pipe until it forces its way out by siphoning it away. For example, the oil pump on an engine uses air compression to keep oil inside the engine rather than letting it just run off in a random fashion. Likewise, a water pump also makes use of such a system. This is commonly used in larger water pumps but can also be used to keep a wide variety of fluids inside pipes - from water and steam to antifreeze and other toxic chemicals.

Finally, there are also structural applications for these pipe fittings. At the very basic level, jointless connectors allow two pipes to connect to one another, with no joint lines necessary. Such a device might be useful for putting two drains and sewage pipes in place at the same time or for connecting a pipe to a lower pipe. More complex connections could use such a device to join a series of deeper pipes to one single pipe - this type of application is more common in building projects where joints need to be exact. In any case, the simple use of two pipes to create something as ornamental as a decorative joint is quite commonplace. In structural applications, a pipe fitter is needed for installing the correct number of joints and to fix them correctly - the wrong number and you'll get a construction disaster.